A study conducted across 20 countries found that 90% of construction projects experienced cost overruns, with an average of 28%[?].

What Is Supply Chain Management in Construction

Supply Chain Management (SCM) is a process that coordinates the movement of materials, information, and finances across all stages of a construction project.

-

Materials. Sourcing raw materials. Controlling inventory levels. Managing production (e.g., manufacturing), transportation, and delivery to the construction site.

-

Information. Ensuring real-time visibility of design decisions, delivery schedules, and procurement statuses. Keeping everyone informed about potential disruptions. Sharing data among contractors, architects, suppliers, and subcontractors via a cloud-based ERP system.

-

Finances. Managing purchase orders and payments. Coordinating funding.

Benefits of Supply Chain Management in the Construction Industry

- Timely project completion. Effective supply chain management ensures that materials and resources are available precisely when they are needed. It minimizes delays, reduces idle labor, and avoids schedule disruptions.

- Cost reduction. A well-structured SCM strategy identifies what your budget is spent on, including high-expense areas. By addressing these weak points, companies can reduce costs, allocate budgets more effectively, and improve overall financial performance.

- Risk mitigation. SCM frameworks help identify and address supply chain disruptions—from bad weather to material unavailability before they escalate.

- Improved reputation. If you consistently complete projects on time without compromising quality, it will contribute to your reputation. Strong SCM helps build trust with clients and partners, improving the chances of winning future bids and forming strategic alliances.

- Centralized data. If you use an SCM platform, you can combine all project data in one place. You will be able to find schedules, procurement, and supplier information inside one ERP system. This enhances collaboration, enables data-driven decision-making, and supports the use of advanced analytics.

Optimize procurement with FirstBit

Key Steps of Supply Chain Management in Construction

1. Planning

-

Set project goals based on what you’re going to build.

-

Define what kind of materials your project needs.

-

Start demand forecasting to determine their quantity.

-

Add as many details as possible. For example: color and specific brand of every material.

-

Outline the project’s timeline, including information about its budget, so you can schedule deliveries and payments.

-

Assess risks like lead time delays or supply disruptions.

Pro tip: The decision-making team should always include the owner, architect, and engineer.

2. Sourcing

Pro tip: Some materials may require long lead times (sometimes months) to manufacture or import. Early ordering is essential to prevent schedule hold-ups.

3. Production

-

Fabrication. Converting raw materials into usable components (e.g., steel frames, MEP modules, custom tiles).

-

Processing and finishing. Adding coatings, cutting to dimensions, polishing, or assembly.

-

Quality checks. Ensuring materials meet specified standards before leaving the production facility.

4. Delivery and Logistics

-

Flatbed trailers are ideal for oversized, irregularly shaped, or bulky materials (e.g., heavy beams, modules).

-

Dry van trailers offer enclosed protection for general, non-sensitive items like boxed materials, fixtures, and packaged supplies.

-

Reefers (refrigerated trailers) are necessary for temperature-sensitive materials (e.g., adhesives, sealants), especially in extreme climates.

Pro tip: Implement proper cargo securing methods, including straps, blocking and bracing, dunnage, and load distribution for safe and damage-free transit.

5. Installation

-

Just‑in‑time delivery. Schedule materials to arrive shortly before the installation phase to avoid cluttering the site or blocking critical spaces. Early deliveries may create staging chaos; late ones halt work and waste labor.

-

Designated staging areas. Establish dedicated staging zones near installation areas. Group materials by trade, task phase, or sequence. Keep fragile or weather-sensitive items protected, and position high-turnover supplies closer to where they'll be used.

-

Inventory tracking. Implement tracking checkpoints at key hand-offs: warehouse exit, jobsite arrival, staging area receipt. Use barcode or QR scanning to log materials. You can also use an ERP software to track inventory in real time.

Top Supply Chain Management Strategies for Cost Efficiency

1. Hire Supply Chain Professionals

-

Leverage specialized staffing firms. Collaborate with agencies that focus on supply chain and logistics recruitment. This approach provides access to candidates who possess the ideal combination of technical expertise, procurement knowledge, and project coordination skills.

-

Offer high-quality training. Topics you can include in the program are ERP systems, supplier relationship management, AI-enabled forecasting, sustainability, and risk mitigation.

-

Define clear career roadmaps. Enable cross-functional mobility across roles in procurement, logistics, inventory control, and project delivery. Such cross-functional rotations can help develop versatile skills and improve employee retention.

2. Unite Supply Chain Teams

-

Serve as the single point of contact across all groups and locations.

-

Foster supplier relationships during procurement.

-

Create standardized operating procedures.

-

Analyze KPIs and initiate dialogue with various teams to address areas of inefficiency.

3. Build Alliances with Suppliers

- Create shared goals. Define performance targets for delivery, quality, cost of production, and sustainability. Use key performance indicators (KPIs) to maintain alignment and drive improvement.

- Engage in collaborative frameworks. Openly communicate each party’s responsibilities. Create a protocol for decision-making meetings, during which you can exchange feedback. Consider multi-year purchasing agreements that can provide long-term stability in the future.

- Monitor the partnership. Conduct periodic performance reviews using KPIs for on-time delivery, quality, and cost. Additionally, you can adapt new goals and processes in response to feedback from suppliers or changing market conditions.

4. Buy Supplies in Bulk

-

One-time bulk orders. You can make a single large purchase for high-demand materials. It can be useful for major projects or long-term stock needs.

-

Blanket purchase orders (BPOs). This is a long-term agreement with a supplier that sets fixed prices and quantities over a defined period, typically up to one year. It enables flexible delivery as needed, protects you from cost increases, and supports inventory stability.

-

Greater operational efficiency (you can make fewer purchase orders)

-

Budget predictability and improved forecasting

-

Stronger supplier relationships during a long-term period

-

Less flexibility to choose different suppliers

-

Fixed pricing may be disadvantageous if market prices drop

-

Requirement to meet minimum purchase commitments or face penalties

5. Create a Safety Net From Multiple Suppliers

-

Material shortages

-

Geopolitical actions (e.g., tariffs)

-

Regulatory changes

-

Weather conditions

-

Natural disasters

- Segment and qualify alternatives. Identify primary and secondary suppliers, ideally from different regions or with various capabilities. Secondary suppliers should be ready to step in when needed.

- Balance cost and timing flexibility. Evaluate trade-offs: some suppliers may offer lower prices but longer lead times; others may be more responsive at a higher cost.

- Execute strategic sourcing practices. Use order splitting and multiple sourcing to manage risks.

6. Optimize Your Inventory Management

- Conduct inventory audits and categorization. Perform regular inventory audits. Verify quantities, conditions, and locations of materials and equipment across all sites. Update records, using barcode/QR systems or RFID scanning to improve accuracy.

- Utilize digital technology. You can’t always conduct daily audits in person. That’s why inventory management software can help you with real-time tracking. It can also forecast material demands and streamline material transfers across different sites.

- Adopt Just‑In‑Time (JIT) inventory. Deliver materials only when needed. Time their arrival just before use. This reduces on-hand inventory costs and prevents them from taking too much space.

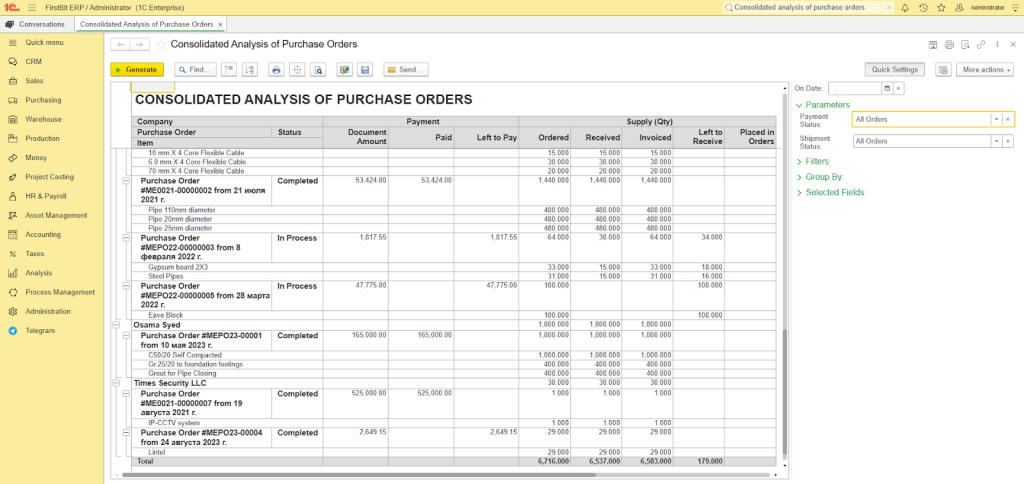

How FirstBit ERP Software Supports Construction Supply Chain Management

-

Consolidated analysis of purchase orders. Track procurement costs to ensure they align with financial plans and don’t go over budget.

-

Payment schedule report. See when payments are due to ensure timely deliveries without any delays or holds.

-

Quotation comparison. Gather multiple supplier quotes and evaluate them to ensure you receive both the best price and reliable service.

-

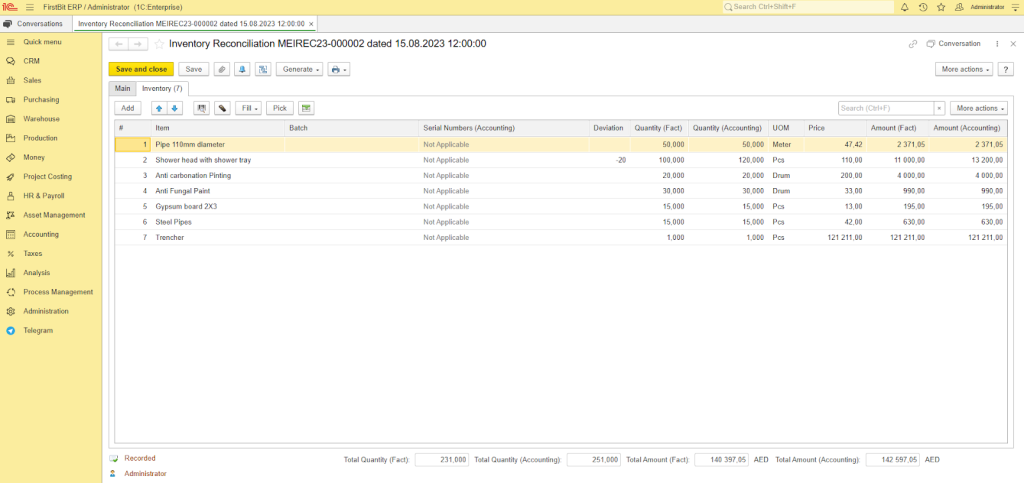

Inventory reconciliation. Verify stock levels and identify discrepancies to achieve accurate inventory reports.

Conclusion

Track orders with FirstBit

FAQ

See FirstBit ERP solutions in action

After the demo you will get a quotation for your company.