Construction delays aren’t a question of if, but when. Studies reveal that over 90% of projects experience setbacks, typically running 20–30% behind schedule[?]. Reasons might be different: labor shortages, design changes, or supplier delays. But as a result, you risk losing profit, time, and client trust if you don’t act promptly.

While you can’t prevent all delays, you can minimize their impact. Top-performing managers anticipate them. They use contingency plans, clear communication, and efficient resource allocation to get projects back on track.

In this guide, we’ll explore the impact of delays in construction projects and their causes. You also learn what to do when a delay happens and how to use construction software to detect emerging delays before they escalate.

Impact of Project Delays in Construction

Did you know that 50% of construction projects in the UAE don't finish on time?[?]

Construction delays in the UAE are a systemic challenge that impacts the national economy, where construction accounts for roughly 11 % of GDP[?]. They affect even mega projects like the Zayed National Museum in Abu Dhabi[?], whose opening has been postponed by nearly 15 years. Now it’s scheduled for December 2025. If government-funded projects face setbacks like this, what about others? Let’s explore the consequences of delays.

Financial:

-

Labour costs increase due to overtime and turnover

-

Higher rental costs for equipment, despite downtime

-

Liquidated damages might be enforced up to 10% of contract value[?]

Operational:

-

Tight schedules lead to mistakes, safety risks, and reduced quality

-

Employee burnout negatively affects efficiency

-

Rescheduled deliveries disrupt the supply chain

Stakeholder and reputational:

-

Lack of trust between clients, contractors, and investors

-

Reputation can suffer long-term

-

Difficulties with securing future contracts

Classifications of Delays in Construction Projects

Delays in construction projects are typically categorized based on their causes, impact on the schedule, and eligibility for compensation. This approach makes it easier to determine who is responsible, manage contractual obligations, and plan what to do next.

Critical vs. Non-Critical Delays

Critical delay is a delay in the task that postpones the project completion or a key milestone by the same duration.

Examples: late building permit approval, unresolved design issue on structural system, extended delay in critical equipment delivery.

Non‑critical delay is a delay affecting tasks off the critical path that have float. These do not delay the project’s end date as long as they remain within their float buffer.

Examples: delay in exterior landscaping, postponement of non-essential fixtures, minor supply chain hold-ups for decor elements.

Excusable vs. Inexcusable Delays

Excusable delay is caused by events beyond the contractor’s control and not due to their negligence or planning.

Examples:

-

Extreme weather, pandemics, natural disasters

-

Delayed inspections or permits, or late scope/design changes

-

Employer-caused delays: withheld approvals, blocked access to the site

-

Third-party disruptions, e.g., civil unrest, supply‑chain collapse

Inexcusable delays result from the contractor's actions, omissions, or foreseeable risks.

Examples:

-

Poor planning or scheduling

-

Inadequate labor or equipment

-

Late procurement or site mobilization

-

Failure to follow a Notice To Proceed (NTP)

Compensable vs. Non-Compensable Delays

Compensable delay is a subtype of excusable delay caused by the project owner or other contractor parties (e.g., design revisions, withheld approvals).

Delay must affect a critical task to qualify; non-critical ones don’t get compensated.

A contractor is typically entitled to both an Extension of Time (EOT) and reimbursement of direct/indirect costs (e.g., labor rates, equipment, overhead).

Examples:

-

Requested changes during construction

-

Delays by the owner in approving shop drawings

-

Change orders issued late by the client

-

Employer-caused suspension of work

Pro tip: Gather all required documentation to support the cost claim. Include proof that delay affects critical path work, owner causation, and timely notice.

Non-compensable delay is also an excusable delay caused by forces outside both contractor and owner (e.g., extreme weather, labor strikes), not attributable to the owner.

The contractor usually receives an EOT only, but no financial reimbursement—each party bears its costs.

Examples:

-

Unusually severe storms that are not typical for the season

-

Independent labor strike

-

Natural disasters or force majeure events

Stay ahead of delays

Monitor project progress with FirstBit

Request a demo

Common Causes of Delay in Construction Projects

Delays in construction often stem from a mix of predictable risks and unexpected disruptions. Understanding both types is critical for project managers who aim to plan ahead and respond effectively when setbacks occur.

Expected Causes

These causes of delays can be managed with better planning and oversight.

-

Late payments. When planned funding fails to arrive on time, due to delays in bank transfers or slow client payments, work stalls. Cash flow gets disrupted.

-

Cost overruns. Budgets that are unrealistic or too tight can quickly drain cash reserves. This leads to procurement delays, halted operations, and re-scoping.

-

Poor crew management. Ineffective scheduling, weak supervision, and inefficient task assignments can result in idle labor, reduced productivity, or even cascading delays.

-

Ineffective communication. Disjointed communication channels, combined with unclear protocols, often result in misunderstandings, duplicated work, and costly rework.

-

Inadequate planning. Lack of buffers, bad task sequencing, and incomplete risk assessments lead to bottlenecks that cause unmanageable timelines.

-

Scope and design changes. Every change requires contract updates and rescheduling. This disrupts the overall project flow.

-

Contractor and subcontractor performance. Frequent crew absences, low quality of work, and missed deadlines from third parties significantly delay project delivery.

-

Client approval delays. Slow approvals of design submittals and change order requests frequently become critical path issues that halt work.

Unexpected Causes

These are more difficult to predict and may be out of the project team's control.

Examples:

-

Adverse weather and environmental conditions

-

Equipment failures and supply chain disruptions

-

Vandalism, theft, or site accidents

-

Political factors or legal obstacles

-

Pandemics

General Rules for When a Construction Delay Happens

When a delay happens, you can manage it if you have a plan. The following steps can help minimize the impact of delays and keep your project on track.

This is what you can do:

- Assess the situation. Quickly find the root cause of the delay. Is it an internal delay, like staffing or equipment issues? Is it external, like weather or permits?

- Communicate clearly and quickly. Notify everyone leading the project immediately. Transparent communication helps manage expectations and maintain trust. Share what caused the delay, how it affects the timeline, and what steps are being taken to fix the problem.

- Replan the schedule. Revise your project timeline to reflect the delay. Use project management tools to adjust task order and durations. Look for opportunities to compress or fast-track work to recover lost time.

- Adjust the budget and contracts. Look at the financial impact of the delay. Change the budgets and, if necessary, revise contracts or issue change orders.

- Monitor and adapt in real-time. Use enhanced monitoring to stay ahead of any further issues or delays. Use dashboards or reporting tools to track progress and make rapid adjustments as you get more information about the situation.

- Follow contractual delay notification procedures. Many UAE contracts require notice of delay within 30 days of the occurrence. Not doing this will lead to penalties.

- Conduct post-delay review. When everything has been res

Ensure timely and profitable project completion with FirstBit

Request a demo

Best Strategies for Each Cause of Delay in Construction

You may not be able to avoid every construction delay, but you can minimize its impact by taking proactive measures. The strategies below can help project managers reduce the likelihood of delays and manage them effectively when they occur. They consist of step-by-step plans tailored to address specific causes of delays in construction projects.

Delays Caused by Financial Challenges: Solution

When you’ve already sent an invoice, but planned funding falls short or arrives late, your progress often halts. Whether it happened due to bank delays or slow client payments, here’s how to recover from this delay in construction:

- Act immediately: claim your contractual entitlements. Put the employer (or their bank) on formal notice that lack of funding has stalled the schedule. Concurrently submit an Extension of Time (EOT) claim plus a separate financing and/or disruption claim, backed with evidence (bank correspondence, payroll reports, etc.).

- Bridge the gap: use short‑term liquidity tools. Arrange for invoice factoring or commercial bridging loans—these can often be fast‑tracked in under a week.

- Restructure cash flow. Agree upon a milestone‑based billing: key achievements (site mobilization, key milestones) should trigger payment quickly. Shift to electronic invoicing by using invoicing software such as FirstBit, which includes automatic reminders for late payments.

- Develop a recovery schedule. Prioritize activities that can proceed without full funding or that require minimal upfront materials or labor costs.

If a construction delay was caused by cost overruns, you can find more tips in our comprehensive guide to managing project cost overrun.

Delays Caused by Poor Crew Performance: Solution

Poor crew performance often coincides with inadequate crew management. That’s why you need a complex set of measures to address both issues effectively.

- Measure crew performance. Use time cards to track when contractors clock in and clock out. Record how many hours each crew spends on each major task. Note the number of reworks needed afterward. Ask the site supervisor to report on situations when the crew is experiencing idle time (e.g., before material delivery).

- Introduce weekly meetings. During these times, superintendents, foremen, as well as subcontractors, need to review real-time sequencing, confirm readiness, and reassign crews as necessary. They can also break down weekly plans into daily goals.

- Foster strong supervision. Define the site hierarchy: for every 10-15 crew members, there should be a foreman with clearly defined authority.

- Teach them problem-solving skills. Train them to monitor productivity, safety, quality, and crew morale. This way, foremen can deal with recurring issues before they cause delays.

- Implement ERP software. FirstBit ERP can help you allocate labor where it’s needed the most to avoid shortages or overstuffing. You can also use it to monitor attendance and analyze performance data.

Delays Caused by Ineffective Communication: Solution

Here is how to create strong communication systems to get the construction project back on track:

- Stop miscommunication. Compile a list of all active RFIs, change orders, and email threads. Identify which contain the misinformation/errors in data that lead to project delay. Tag those needing immediate follow‑up.

- Rebuild the system. Create and distribute a Communication Management Plan (CMP). Then you need to notify everyone. Send a memo stating: “As of this morning, all formal communication must go through [1-2 chosen channels]. No exceptions” and attach a file with CMP.

The CMP defines:

-

Who talks to whom (for each type of team member, specify who is responsible for answering their questions)

-

What must be communicated: RFIs, design changes, daily safety report, project delays, etc.

-

Through which channel (email, software, messaging app)

-

When (immediately, daily, weekly)

-

Format and naming rules (e.g., “RFI‑123_Yellow column”)

Delays Caused by Inadequate Planning: Solution

When lack of effective planning is the cause of a construction delay, a structured schedule recovery is the remedy.

- Run a time impact analysis[?]. Compare the original baseline with the actual data (both as-built and as-planned) to quantify the schedule delay, so you can identify the tasks affected by it.

- Check the schedule for problems. You need to look for a negative float (when an activity's available time buffer is below zero) or illogical dependencies (when task relationships are established incorrectly).

- Identify the critical path. Use the Critical Path Method (CPM) to identify the most critical tasks that must be completed to successfully finish the project.

- Add time buffers. Insert buffers before critical milestones, handoffs, or permitting to protect your timeline against future unknown disruptions.

Delays Caused by Scope and Design Changes: Solution

Here is what you can do to adjust the schedule after the scope or design change and resume the work.

Sort out changes

Create a central log of all upcoming changes and group them by:

-

Source: Owner request, design error, etc.

-

Status: “Estimated Time Impact Analysis” | “In negotiation” | “Signed by contracting officer's representative”

-

Critical path impact: No / Near‑critical / Critical

Control COR Process

Establish a Change Control Board (CCB). This central group (project manager, designer representative, contract administrator) adjudicates change requests based on priority, cost, schedule, and contract terms. You also need to pre‑establish approval thresholds (e.g.,> two working days).

Suggest a standardized Change Order Form (COR) for everyone to follow. Each request can include:

-

Description of change

-

Reason – e.g., owner-initiated, unseen condition

-

Separate time/cost estimate

-

Contract clause reference

-

Effects on milestones

-

Attachments – design drawing, markups, photos

-

Review deadline (e.g., 72 hours).

Execution

Sort CORs by how critical they are to complete. Start with critical changes; until you finish them, delay non-essential ones. Update your schedule by creating a new Critical Path Method (CPM) analysis that incorporates the latest changes and phase durations.

How FirstBit Can Help Manage Delay in Construction Contracts

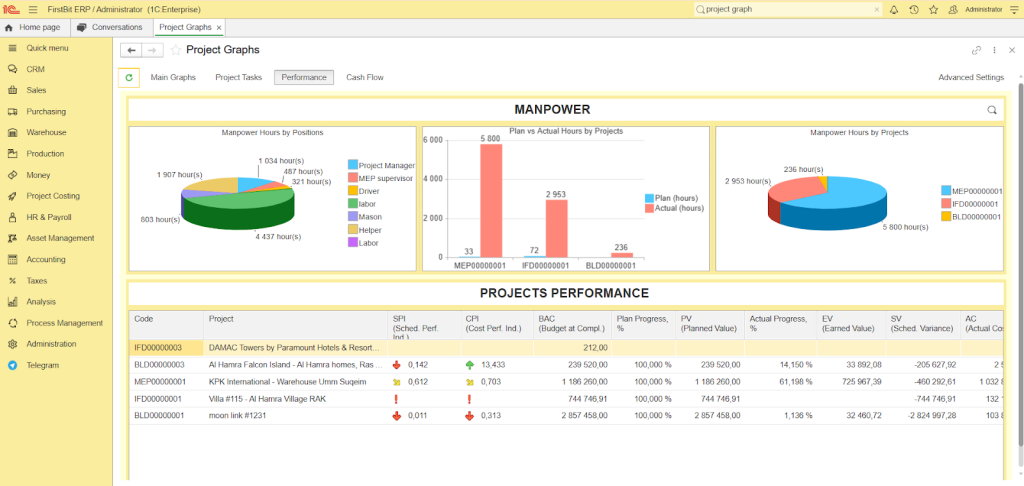

FirstBit provides clear visibility into project progress, finances, and labor. Each feature is designed to help you identify warning signs early and address issues before they escalate into costly delays.

-

Project performance dashboard. Track vital KPIs in real time—such as schedule performance and task progress. So you can quickly notice when you are at risk of falling behind schedule and take early corrective action before delays become critical.

-

Project tracking with a Gantt chart. Use a visual timeline to analyze task dependencies. When one task is delayed, you can quickly identify the other tasks that will be affected and take appropriate measures to address the impact.

-

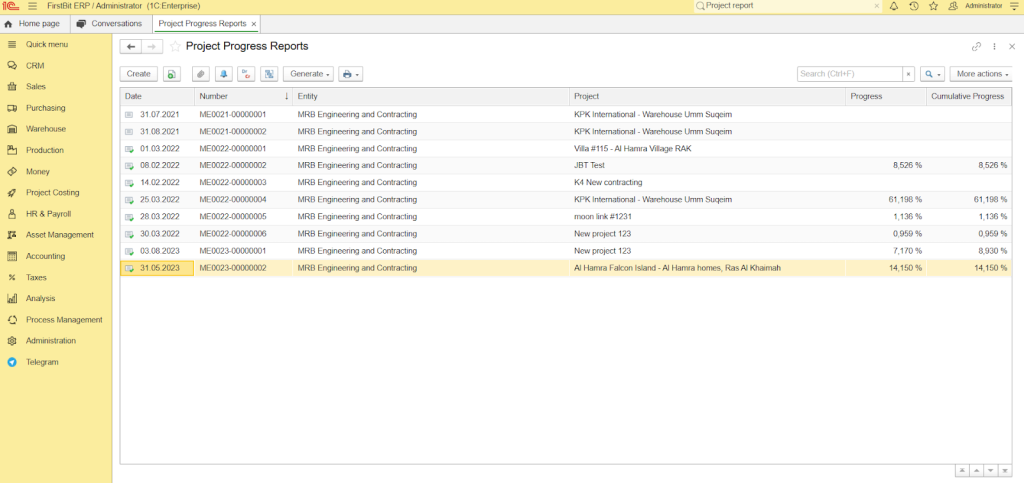

Project progress report. Get an update for each BOQ line to verify that the actual completed work aligns with the official project schedule.

Project progress reports by FirstBit ERP

-

Time cards. Keep precise records of labor hours to monitor and prevent regular absences that can cause labor shortages or even reduce productivity.

-

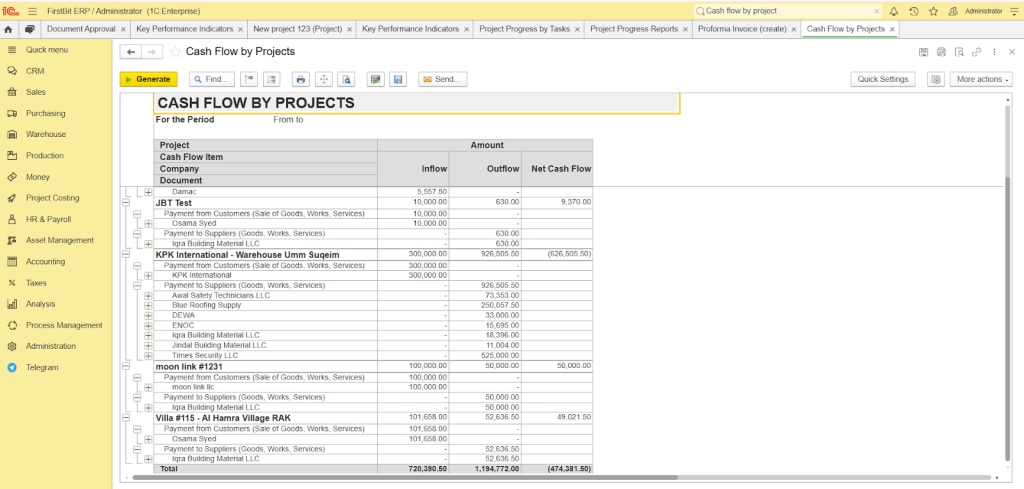

Cash flow by project. Track cash inflows and outflows, so you can spot potential budget overruns before they cause delays.

Achieve flawless teamwork

Coordinate roles and schedules through FirstBit ERP

Request a demo

Conclusion

Construction delays are unavoidable—but with the right tools and strategies, their impact can be significantly reduced. Proactive planning, clear communication, and real-time performance tracking are essential in preventing minor setbacks from becoming major disruptions.

Beyond reactive measures, construction firms must invest in systems that support continuous improvement and data-driven decision-making. FirstBit’s ERP software plays a key role here. It helps you track project progress, monitor finance, and manage resources. This strategic advantage can help you protect your profits, reputation, and long-term success against any delays.

Christa Tintelnot

Contributing Author

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.