Across the construction sector, many projects still rely on outdated systems, fragmented communication, and isolated data. Teams work from different versions of the truth, delays go unnoticed until they escalate, and critical insights never reach decision-makers in time. These inefficiencies slow delivery, increase rework, and erode already-thin margins.

Digital transformation is a priority for 72% of construction firms worldwide. Yet 32% still spend less than 3% of their turnover on digital technologies. The will to modernize exists, but without meaningful investment, progress remains limited[?].

Connected construction offers a way to close this gap. By integrating people, systems, and data in real time, it creates a single, reliable foundation for planning, execution, and decision-making across every stage of a build.

This article explores how connected construction works, the operational problems it addresses, and the steps to successfully implement it in your business.

What is Connected Construction

Connected construction is a digitally integrated approach to managing construction projects. It links teams, systems, equipment, and data through cloud-based platforms and smart technologies. Each stage of the project — design, procurement, field operations, and handover — remains continuously updated and accessible across departments and locations.

This model moves away from isolated workflows, spreadsheets, and delayed communication. Instead, it establishes a real-time digital environment where project managers, site supervisors, subcontractors, and clients work with the same data. Tools such as IoT sensors, mobile apps, and digital collaboration platforms keep progress updates, material deliveries, and safety measures aligned.

The purpose is to build a process that is more adaptive, efficient, and transparent. Connected systems help reduce downtime, detect issues earlier, and improve planning and resource use. As projects grow in scale and complexity, this model supports consistent delivery and stronger control over scope and timelines.

Key Advantages of Connected Construction

Shifting to connected construction isn’t just a technological upgrade; it directly impacts how projects are delivered. From daily site coordination to long-term cost control, the benefits show up across every stage of a build.

Collaborate More Effectively Across Teams and Locations

When information is delayed or misaligned, even well-planned projects can face avoidable setbacks. Disconnected updates between site crews, consultants, and project managers often lead to rework, delays, or overlooked details.

A connected construction approach replaces fragmented communication with a shared digital environment. Plans, schedules, RFIs, and approvals are updated in real time and accessible to all stakeholders, whether they’re on-site or in the office.

This improves decision-making speed, ensures version control, and reduces manual coordination. For your team, it means fewer misunderstandings, faster issue resolution, and greater confidence that everyone is working from the same source of truth. On large or fast-moving projects, that clarity can translate directly into time and cost savings.

Improve Safety While Increasing Efficiency on a Construction Site

Preventable delays and accidents often stem from unclear protocols or late identification of site risks. Without real-time visibility, it’s harder to act on issues before they escalate, and small problems can quickly become costly disruptions.

Connected construction helps you shift from reactive to proactive site management. With live data feeds from wearables, equipment sensors, and mobile inspections, you gain a continuous view of safety conditions and progress.

This allows you to track workforce movement, identify hazards as they arise, and ensure compliance with safety standards — all without pausing the work. For your operations, this means fewer incidents, more consistent productivity, and better use of on-site resources.

Instead of chasing updates or waiting for paper reports, your teams stay focused on building with fewer interruptions and a stronger safety record.

Lower Costs and Stay Competitive in a Challenging Market

Margins in construction are often thin, and the pressure to deliver under tighter timelines and stricter budgets. It is only increasing. How do you protect your profitability while meeting rising client expectations?

Connected construction offers a direct path to smarter cost control. By linking scheduling, procurement, labor, and reporting in real time, you can spot inefficiencies early and act before they drain your budget.

Access to centralized project data allows you to avoid rework, reduce material waste, and allocate labor where it's most needed. Automated tracking tools help ensure suppliers are on time and within budget, while mobile apps allow your teams to log time, issues, and changes from the field instantly.

For your business, this translates into leaner operations, tighter estimates, and faster project delivery, all of which strengthen your position when competing for new contracts.

Make Better Use of Project Data Without Code

Construction teams are generating more data than ever — from jobsite updates and material deliveries to equipment usage and safety reports. But collecting data is one thing. Making it useful is another.

How can you turn daily activity into real business insight without needing a full-time data analyst?

Connected construction systems make that possible. Modern platforms now offer no-code and low-code tools that let your site managers, engineers, and coordinators build dashboards, automate workflows, and track performance without writing a single line of code.

For example, a field supervisor can set up a simple form to log equipment malfunctions and automatically trigger a maintenance request. A project manager can create a dashboard showing budget usage across multiple jobs in real time — no IT department involved.

This approach puts decision-making power in the hands of the people closest to the work, speeding up reactions and reducing dependence on back-office teams. When everyone can work with data, your business becomes more agile, more informed, and better equipped to adapt.

Connect your office and site teams

Synchronize workflows and approvals with FirstBit

Request a demo

A Roadmap for Getting Started with Connected Construction

Shifting to a connected construction model doesn’t happen overnight. It requires thoughtful planning, the right tools, and consistent team engagement. Here’s how to build momentum without disrupting daily operations.

Identify Where to Begin for Maximum Impact

Before investing in new tools, assess your current processes. Where are the delays happening? Are teams struggling with duplicate data entry, missed updates, or disconnected systems?

Look for areas where inefficiencies create real cost, like delays in approvals, rework due to miscommunication, or manual reporting. Starting with one or two clear use cases ensures early wins and helps build internal buy-in.

Select Tools and Software That Fit Your Construction Business

Not every digital platform is built for the pace and complexity of construction. Choose tools that reflect how your teams work in the field, across sites, and often under pressure.

Look for systems that are:

-

Easy to adopt. This means teams can start using them without steep learning curves

-

Mobile-friendly. This feature will help you stay connected on-site, not just at a desk

-

Able to integrate. The data flows across finance, scheduling, and procurement without manual input

If you're managing multiple jobs or departments, a construction-specific ERP system can help bring everything into one place — from budgets and schedules to workforce planning and document tracking.

A system like FirstBit ERP offers a setup that improves visibility and coordination by giving you a clear, real-time view of project status across teams, and enhances coordination by keeping everyone aligned on updated plans, materials, and timelines all within a single platform.

Adopt Change Gradually for Long-Term Success

Introduce connected construction tools in manageable phases.

Start with one department or a single jobsite. Choose a pilot team that’s open to change, and focus on solving one or two specific problems, like improving site reporting or automating purchase approvals. Once the process proves successful, use that momentum to expand adoption across the business.

This phased rollout helps teams adjust at a steady pace while minimizing risk. It also allows you to gather feedback early, fine-tune your workflows, and ensure the new tools support your business goals. Provide hands-on training and ongoing guidance throughout the transition so teams feel confident using the new systems, not burdened by them.

Taking this step-by-step path not only builds trust but also helps ensure that digital transformation delivers lasting results.

Challenges of Connected Construction and How to Overcome Them

As companies in the construction industry look to adopt connected workflows, they often face issues related to cost, change management, system compatibility, and data security.

Manage Upfront Costs Without Losing Sight of ROI

The high initial cost of connected construction is one of the most cited barriers to adoption. New tools, infrastructure upgrades, and staff training require significant capital investment. For many small to mid-sized firms, this can strain budgets and delay implementation. Without a clear link between spend and return, it's easy to deprioritize digital transformation altogether.

Get Leadership and Teams on Board To Avoid Pushback

Resistance from decision-makers or field teams can stall progress before it starts. Leadership may be skeptical of the value, while site crews might view new systems as disruptive or unnecessary. Without internal alignment and buy-in, even the best-connected tools can go underused or misapplied.

Choose the Right Systems and Be Free From Integration Hurdles

Adopting new tools often leads to a disconnected tech stack. Systems that don’t sync with your schedules, budgets, or reports create friction instead of progress. Without proper integration, teams waste time on double entry, workarounds, or tracking down information across platforms.

Safeguard Your Data From Security Risks

More digital tools mean more entry points for cyber threats. Without proper access controls, encrypted storage, and data backups, sensitive project and financial information is exposed. A single breach can disrupt operations and damage client trust.

Upskill Your Workforce to Improve Digital Literacy

New technology is only as effective as the people using it. When teams aren’t confident with digital tools, adoption stalls and errors multiply. Without training and support, even the best systems go underused, wasting time and investment.

Everything you need for success in one powerful ERP solution

Request a demo

Why Is FirstBit the Best Software for Connected Construction

While connected construction offers transformative benefits, adopting it comes with challenges that must be addressed early. By using FirstBit ERP, you can turn these obstacles into opportunities with practical, built-in solutions.

Managing Upfront Costs

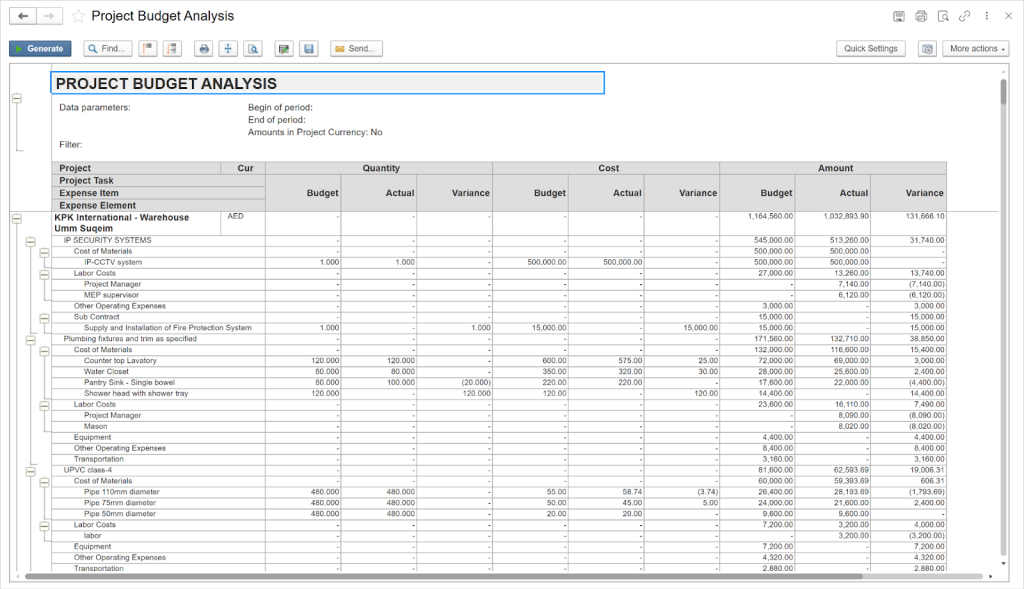

High initial investment in connected construction can strain budgets, especially for smaller companies. In FirstBit ERP, you can create detailed project budgets before committing funds, set profit targets, and link them to every stage of execution.

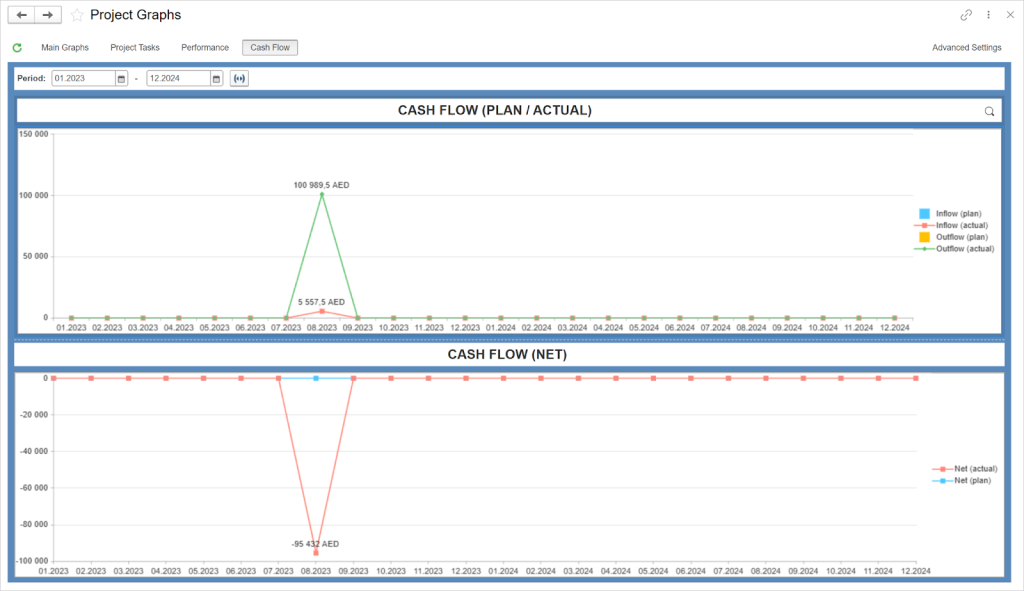

Real-time cost tracking and cash flow dashboards help you see exactly when and where expenses occur, allowing you to adjust procurement schedules or payment terms to protect your margins.

Solving Integration Gaps

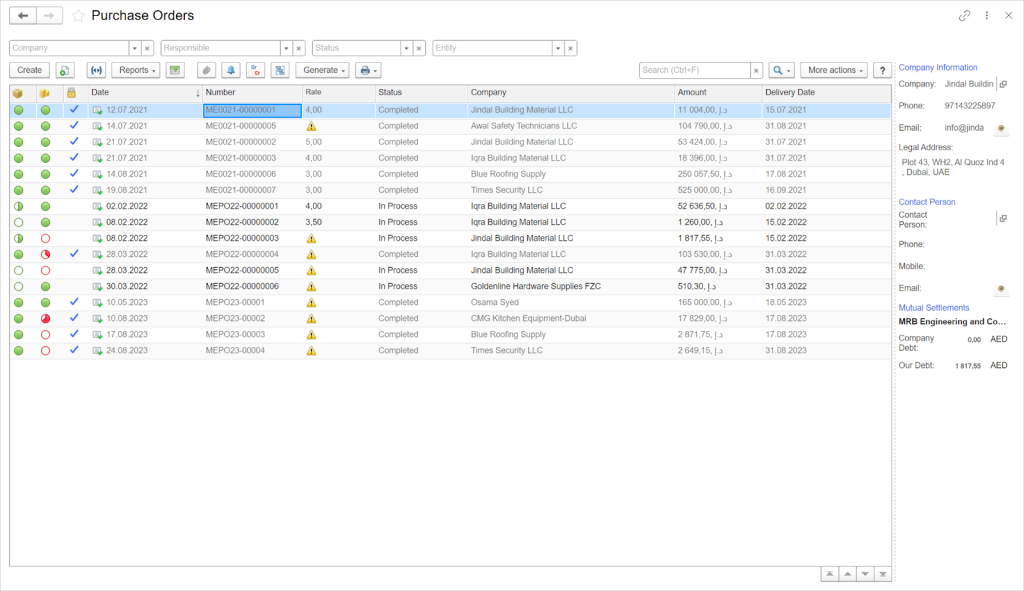

Disconnected tools slow progress and create errors. FirstBit ERP integrates scheduling, budgeting, procurement, HR, and warehouse management in one platform, so you don’t need to juggle multiple systems.

You can import existing schedules, link them directly to cost codes, and have every update automatically reflected in financial and resource plans.

Bridging Digital Skills Gaps

Finally, digital skills gaps can limit the impact of connected construction. FirstBit ERP includes user-friendly interfaces, mobile access, and built-in templates for tasks like purchase orders or cost reports.

New users can start with guided onboarding, role-specific tutorials, and sample workflows so they can contribute effectively without waiting for extensive IT training.

Final Thoughts

Connected construction is a practical way to boost efficiency, visibility, and profitability in today’s competitive market. The difference between struggling with adoption and thriving in a digital-first market often comes down to how well you align technology with your business goals.

By tackling common challenges head-on and using tools designed for your industry, you create a foundation where efficiency, transparency, and profitability can grow together.

Stay on track with your goals

Monitor KPIs with FirstBit ERP

Request a demo

F.A.Q.

1. How can connected construction help reduce disputes between contractors and clients?

2. What skills should my team develop to make the most of connected construction tools?

3. Can connected construction benefit smaller projects, or is it only for mega-projects?

Anna Fischer

Construction Content Writer

See FirstBit ERP solutions in action

Discover how our system solves the unique challenges of contractors in a personalized demo.

After the demo you will get a quotation for your company.

After the demo you will get a quotation for your company.